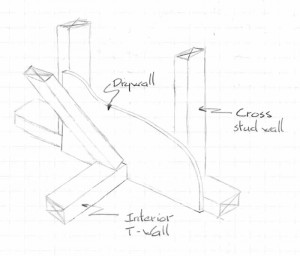

Following up on our previous entry on corner connections which dealt mainly with exterior corners, we can look at intersections between interior and exterior walls, often referred to as T-Walls. These connections create some of the same issues. There is a need for support at the corner structurally and as a connection point for interior finish material. Traditional framing accomplishes this using two additional studs in the cross wall to provide nailing corners for interior finishes. (Figure 1) When the cross wall is an exterior wall, the same issues of maximizing insulation in the exterior wall applies. The additional studs can create an insulation void as well as unnecessary use of additional wood studs.

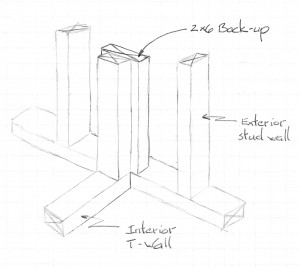

In a room with drywall finishes, one of the most economical and efficient methods of solving these issues is to install drywall continuously on the cross wall prior to installing the T-Wall studs. (Figure 2) This can be accomplished before the cross wall is built or the connecting stud can be left out or loose until after the drywall on the cross wall is installed. This is a technique that is often used in steel stud framing.

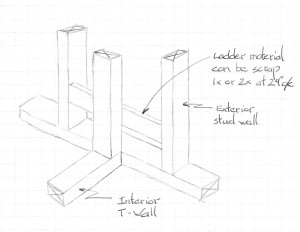

When it is not practical to install the cross wall drywall first, blocking can be used to provide finish support at corners. When the T-Wall is 2 x 4 construction, a 2 x 6 installed within the cross wall can accomplish this. (Figure 3) As this is only there to create a nailing strip, scrap salvaged from roof sheathing, floor decking or other areas can be substituted for the 2 x 6. Also, since the 2 x 6 is not there as structural support, it does not have to be continuous as long as it provides nailing points at least every 24″ o/c.

Further efficiency can be achieved using scrap lumber, 2 x 4 cutoffs, scrap roof and floor sheathing, etc. to create a ladder effect to provide nailing points. (Figure 4) Drywall clips are also a solution, as previously discussed.

These things require planning, but are easily accomplished.

Easterday Construction Co., Inc. will be making every effort to use these more efficient corners for T-Walls on projects as we go forward. Preferably the bypass method, but using salvaged lumber when this isn’t possible. This is Green that saves Green!

Summary

- Reduction in materials required for the job. Two less studs and associated fasteners at each corner.

- Reduction in labor necessary for material installation.

- Reduction in waste material sent to the landfill when cutoffs are substituted for new studs.

- Increase in energy efficiency by increasing the accessible wall cavity and eliminating the heat transfer through the additional studs when this situation occurs with an outside wall.

This should be required reading for carpenters!