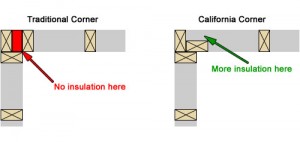

There are several ways we can improve the efficiences in the framing of outside corners. A California Corner is one designation for a wood framing pattern that rotates one of the three studs in exterior corners. On exterior walls this allows insulation to proceed all the way to the corner rather than creating an insulation void.

Both the California Corner and standard framing create a solid inside and outside corner. This provides a fastening point for both the exterior sheathing or finish material and the interior finish material. For example in home construction, there is a stud which forms the outside corner where the sheathing is nailed and there are two studs, one in either direction from the outside corner stud, which form an inside corner allowing drywall to be nailed along the edge in both directions.

Optimum Value Engineering (OVE) uses only two studs in the corner eliminating one stud. There are two basic benefits to this. 1) One stud is saved, translated to labor savings and fastener savings. 2) Where standard framing creates an uninsulated void in exterior corners and the California Corner allows insulation to fill this cavity, OVE further increases the insulation value of the wall system by eliminating one more stud that transfers heat through the wall and allows the full depth cavity for insulation.

Optimum Value Engineering (OVE) uses only two studs in the corner eliminating one stud. There are two basic benefits to this. 1) One stud is saved, translated to labor savings and fastener savings. 2) Where standard framing creates an uninsulated void in exterior corners and the California Corner allows insulation to fill this cavity, OVE further increases the insulation value of the wall system by eliminating one more stud that transfers heat through the wall and allows the full depth cavity for insulation.

If the interior is to be finished, it is necessary to address a fastening point for drywall or other finish material. (Note: In some cases this corner is being allowed to “float”. This option depends on the type of finish material and local code requirements.) This can be addressed by installing blocking. There are always cut-offs available for this on the job site. In the case of drywall, drywall clips can be used.

Easterday Construction Co., Inc. will be making every effort to use either California Corners or preferably OVE corners on projects as we go forward. This is Green that saves Green!

Summary

- Reduction in materials required for the job. One less stud and associated fasteners at each corner. This includes interior partition walls as well as exterior walls.

- Reduction in labor necessary for material installation.

- Increase in energy efficiency by increasing the accessible wall cavity and eliminating the heat transfer through the additional studs.

Your corner ideas is interesting. Do you have anything similar for interior wall to exterior wall intersections?

Mike,

For interior, non-bearing walls our preferred method is to install the interior wall without the last stud at the corner and hold the top and bottom plates just short of the intersecting wall. This allows the drywall to be installed continuously on the exterior wall. The corner stud is then installed. The corner stud can be attached to the drywall with screws and toe-nailed to the top and bottom plate. This also improves the situation with the vapor barrier as it can continue through the wall connection without a gap as well.

This can be done at the ceiling as well where the ceiling drywall is installed first and then the partition wall top plate ends against the ceiling drywall. This only works with non-bearing walls where solid connections are not required. This speeds up ceiling drywall installation as well, eliminating cuts at walls.

Kevin

I found your post on corner framing and its impact on green building practices quite enlightening. The way you’ve illustrated how this technique not only improves energy efficiency but also contributes to cost savings is very compelling. I particularly appreciate your detailed explanation of how corner framing can reduce thermal bridging and enhance the overall insulation of a structure.

Given your expertise in green construction methods, I’m curious about how corner framing compares to other energy-efficient techniques when it comes to integrating materials like stucco. Specifically, how does corner framing influence the performance and durability of stucco applications on the exterior of a building? Are there any additional considerations or best practices for combining these two methods to achieve optimal results?

I am hardly an expert and I don’t have any data driven answers for you. That said, any reduction in heat transfer points is beneficial. We generally try and use 24″ in lieu of 16″ stud spacing where possible to reduce studs, just like California corners eliminate a stud. That said, stucco, when applied over a insulated foam board, provides a continuous thermal break, with the only heat transfer points being the fasteners and those do not pass all the away to the interior. Stucco has gotten a bad rap due to some of the moisture related issues that have occurred. Those were more prevalent in the south, but still occurred in our area too. Newer best practices for installation have cured most of those issues, but for some, the stigma is still there.